X

X

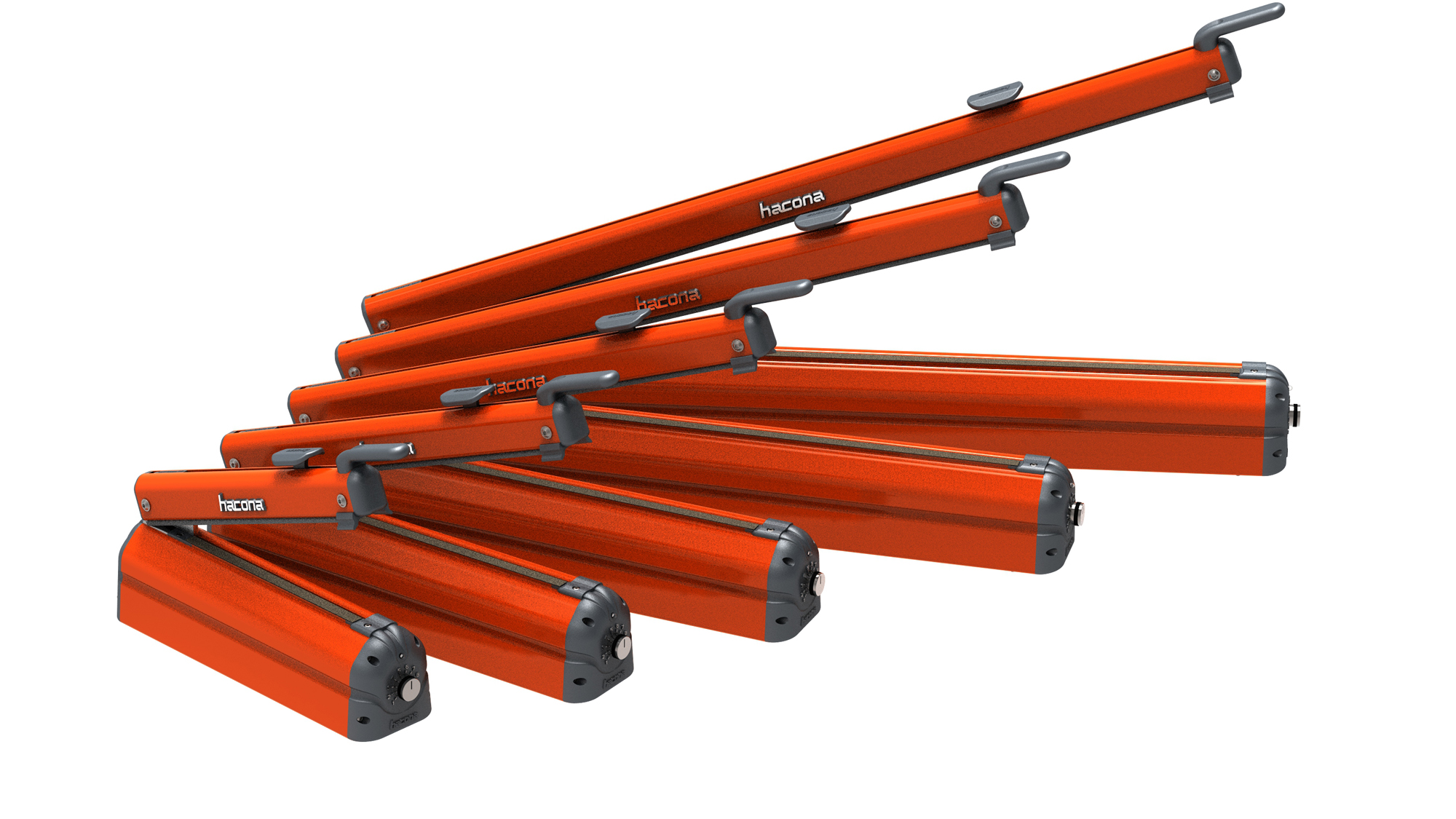

C – type

Ultra strong magnesium aluminum body

Ultra strong magnesium aluminum body

C – type impulse sealing machines / poly bag sealers with powder painted surface

Orange is the color behind the brand. From the very beginning hacona produces all its products with the factrory typical orange color. Perfect look that reflects the quality - is one of the key aspects that our engineers have in mind when they develop a product. We do not accept even the slightest compromise in high quality and top appearance.

The entire film sealing machine is designed to assure the highest safety. The machine body and the connecting parts are mounted so precisely, that there is not even a single gap between them. No free running cables and no openings on the machine frame. It all serves the safety!

CI – type impluse sealing machines / poly bag sealers with silver anodized surface

All CI – types impulse sealing machines / poly bag sealers can be used in food- , pharmaceutical – and chemical industry. By anodizing (surface treatment) the machine frame the surface of the aluminium profile gets absolute smooth and strengthened. With this surface treatment the CI – type film sealing machine frame is now even more resistant agains scretches and mechanical impacts.

Impulse film sealing technology

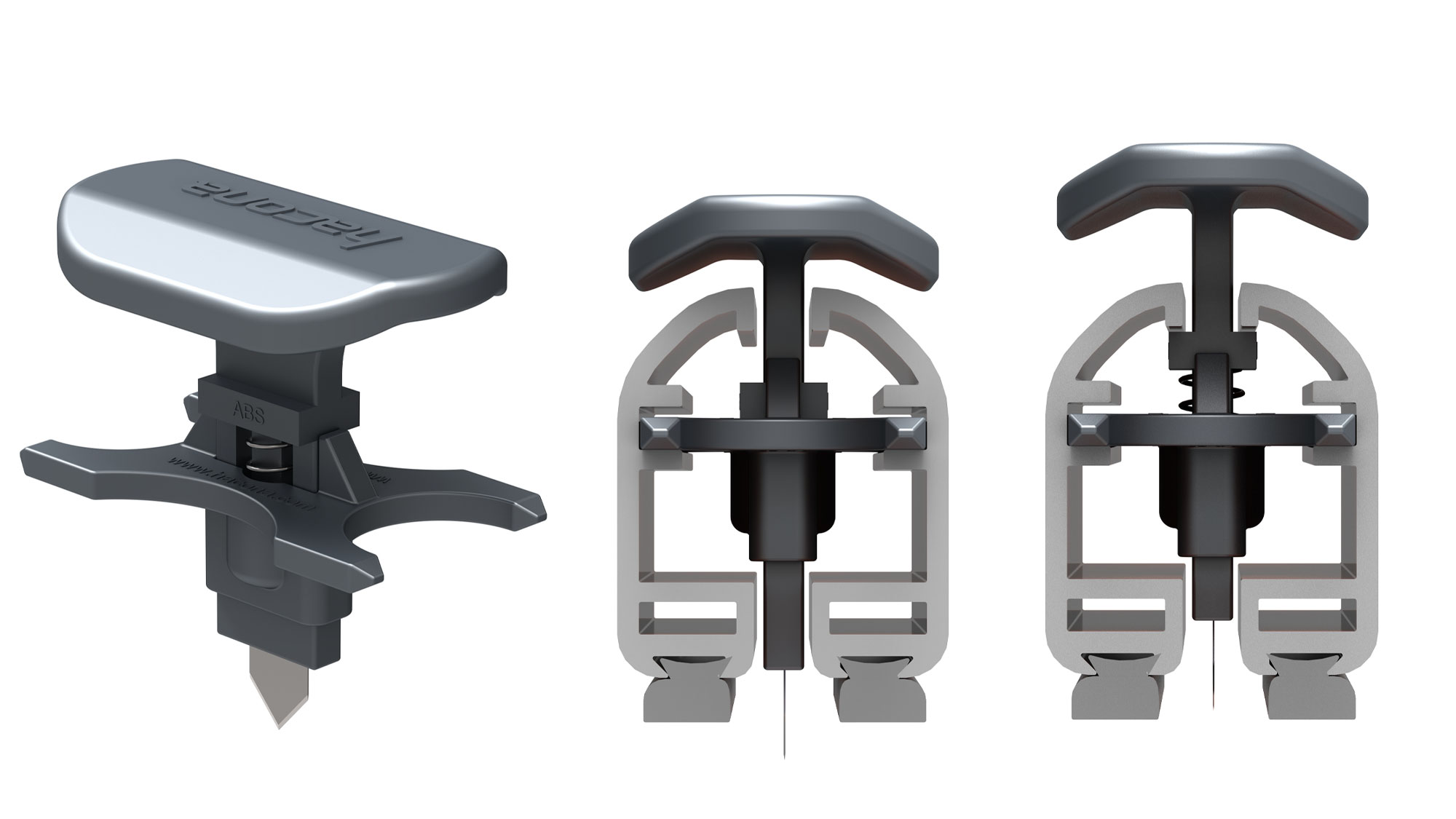

A technology without compromise: The specially designed C-type sealing wire tentioning system assure at any temperature level an optimised sealing wire tention. At high temperature values the sealing wire expends itself. Our sealing wire tentioning system is designed to apply optimum tention at any temperature level and to assure a free movement of the sealing wire in longitudinal direction.

The specially designed upper PTFE tape is designed to underline this function and to assure free movement of the sealing wire on the film sealing machine / poly bag sealer at any time.

Impulse film sealing technology

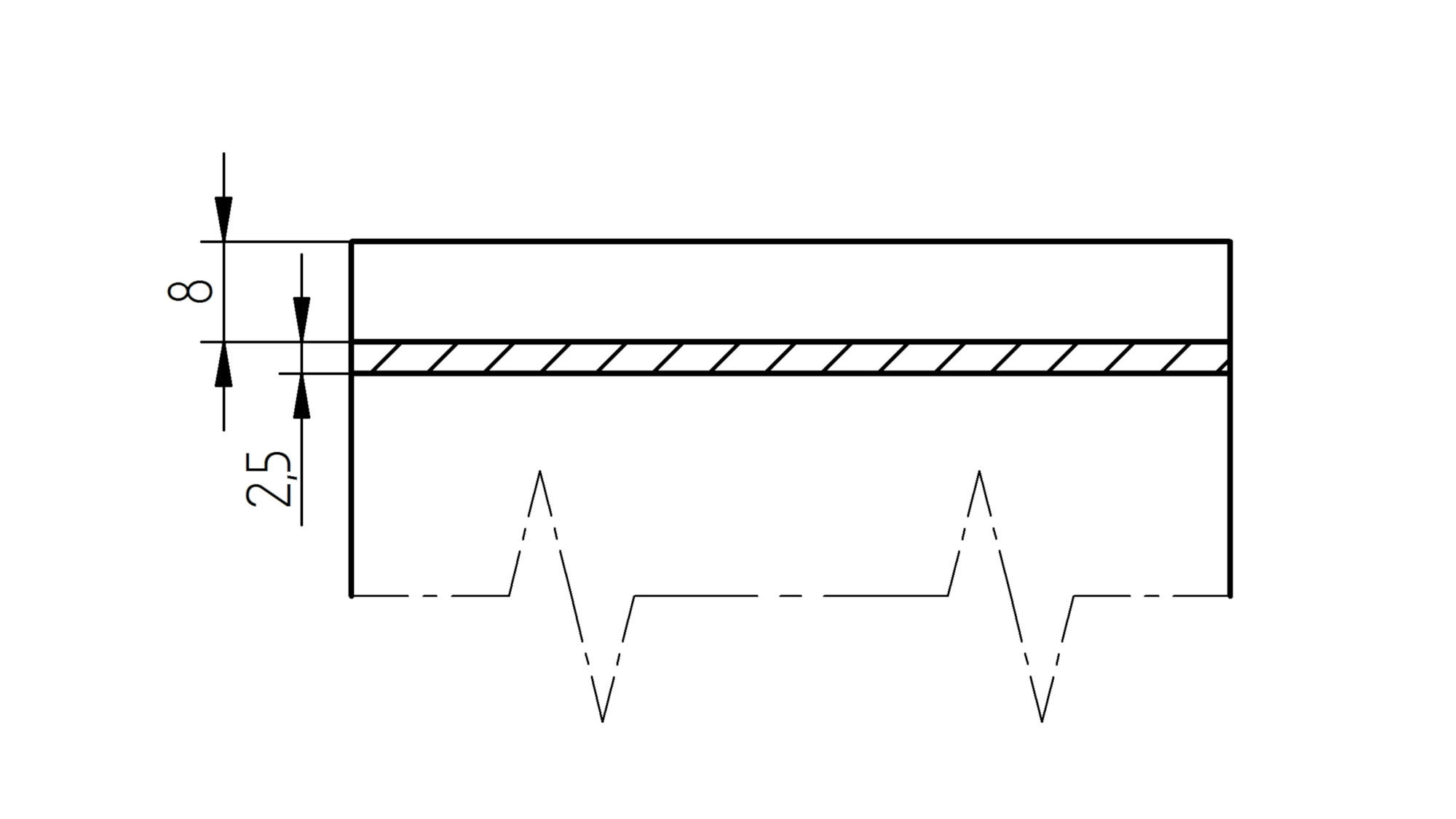

2,5 mm ( app. 0,1 inch) wide sealing wire with impulse sealing technology.

• Power saving

• High level of security

All C-type impulse heat sealers / poly bag sealers work with a 2,5 mm (app. 0,1 inch) wide impulse sealing wire. The sealing length depends always on the size of the machine. All thermoplastic (heat sealable) films up to 200 micron total material thickness can be sealed easily and air tight. The total surface of the sealing wire is PTFE tape coated. This avoids sticking of the bag material to the sealing wire.

The C-type impulse heat sealers / poly bag sealers have an integrated specially designed safety cutting knife system. This cutting knife system enables to produce bags from tube film or to cut the rest of the film off the bag after sealing.

Sealing wire temperature & time control

Stepless adjustement of the sealing time with turning knob.

Adjustment possibility from value 1 – 10

All C-type impulse heat sealers – poly bag sealers can be adjusted in sealing time from value 1 - 10. The sealing wire is time controlled. By adjusting the sealing time the temperature will automatically increase in parallel. The sealing temperature can not be set seperatly. It is not possible to adjust the cooling time on the machine. It is suggested to keep the sealing bar min. 1 second longer closed after the red light turns off.

A LED light above the turning knob shows the present status of the impulse heat sealer – poly bag sealer in operation. If the light is off, than the C-type impulse heat sealer is unpluged (the machine is shut OFF). In this condition the machine can be stored or repaired.

By pluging in the machine the LED light will turn yellow. The C-type impulse heat sealer – poly bag sealer is now in standby mode.

The average consumption in standby mode is app. 2 W / hour (electrical power).

To work with the C-type impulse heat sealing machine and to make a sealing the sealing bar has to be closed. The LED light will turn from yellow to red.

Red light shows, that the machine is sealing. After the adjusted time the sealing will stop and the red LED light will turn again yellow.

For perfect sealing result we always suggest keeping the sealing bars closed under pressure for additional 1 – 2 seconds after the sealing is finished (the red light turns back yellow again).

At hacona SAFETY is not an option! We offer the highest SAFETY standards for all hacona film sealing machines – poly bag sealers.

• SAFETY cutting knife system

All C – type impulse film sealing machines – poly bag sealers have an integrated safety cutting knife sytem to cut off the rest of the bag above the sealing. The cutting knife can be used also to produce bags from tubular film.

The sharp cutting knife system is safely positioned inside the aluminum sealing bar. This assures, that the operator can not cut or hurt himself with the knife before it is activeted.

In order to activate the cutting knife the operator has to push down the knife and move it along the complete sealing bar length. After releasing the knife it will slide back into its safe position.

• Impulse film sealing technology

The sealing wire of the film sealing machine – poly bag sealer heats up only when the sealing bars are closed. The sealing is activated when the sealing bars are totally closed and the LED light turns from yellow to red. If operator opens the sealing bar before the sealing cycle is finished, the heating of the sealing wires will be shut off automatically. NO risk of getting burn injuries.

In standby mode the machine consums only app. 2 W / hour electrical power.

• Totally closed machine body

The entire machine frame is totally closed. There is not even a slight opening or gap on the machine body. There are no free running electrical cables. Each electrical connection is properly hidden.

The sealing wire is covered with PTFE tape on the total length.

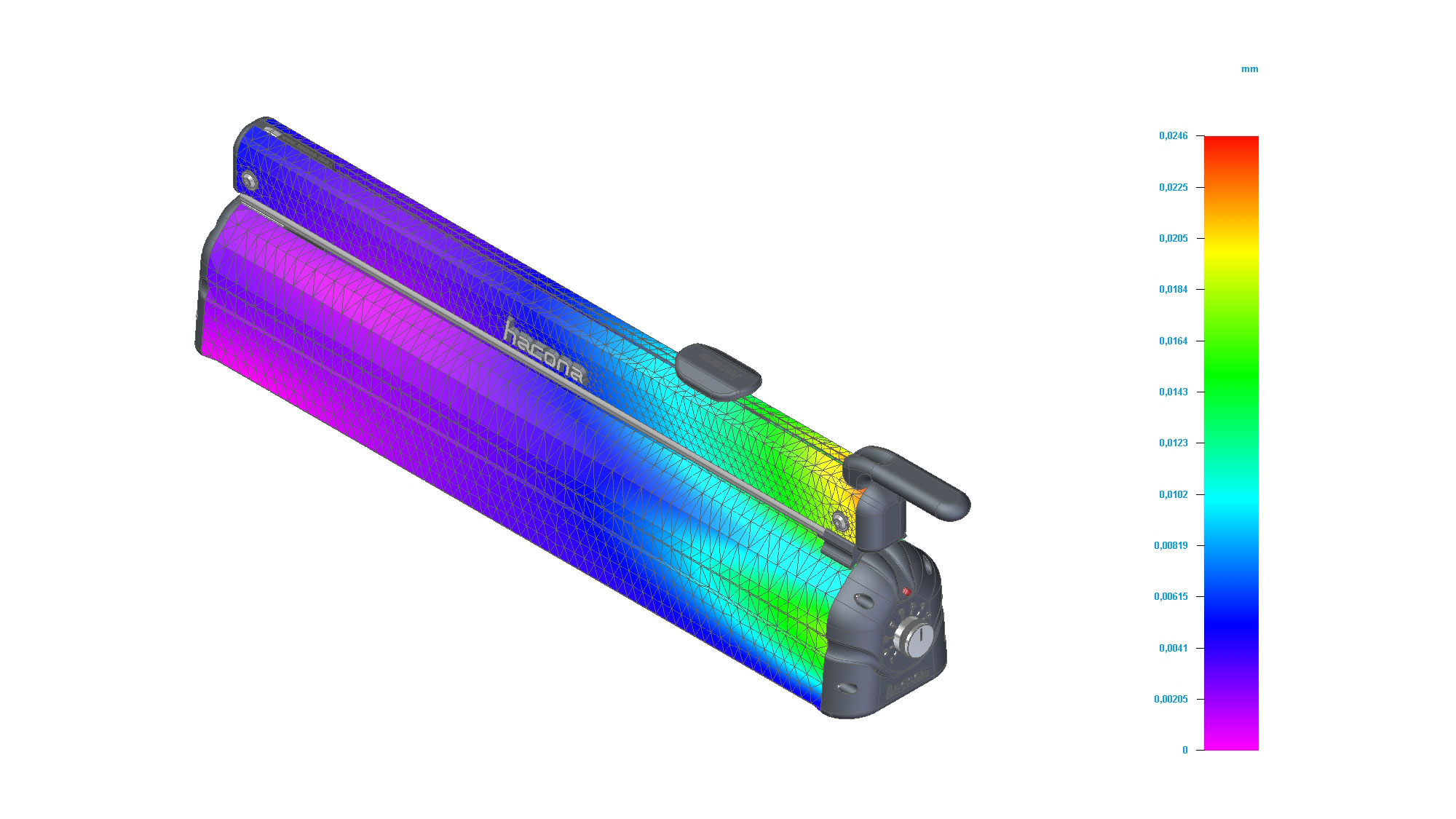

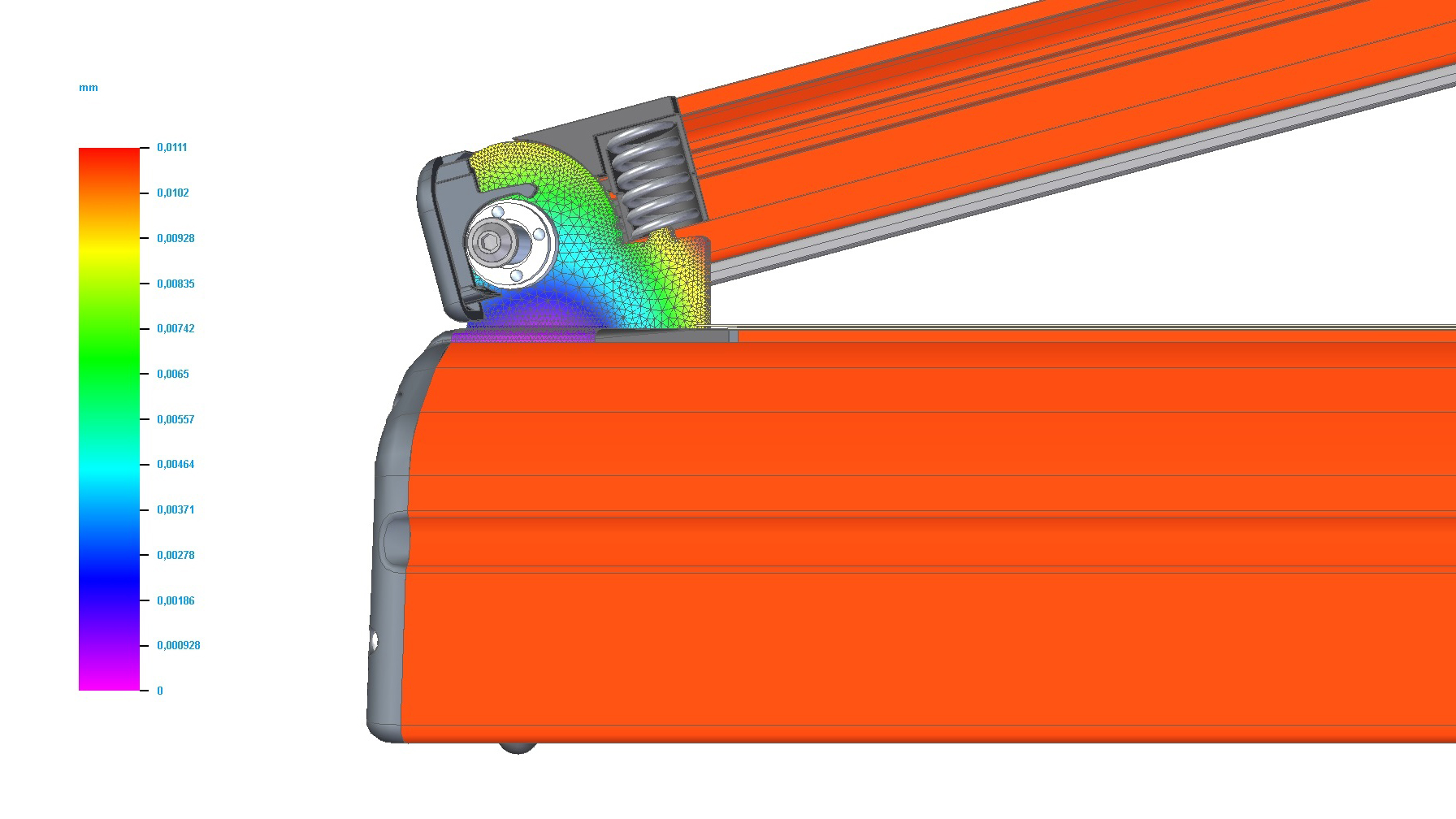

Extra robust magnesium aluminium sealing bar suspension with ball bearing guidance.

The sealing bar and the sealing bar suspension has a special designed geometric form. It is designed to meet high load capacities. By choosing top materials like magnesium aluminium the loadability of the sealing bars is maximized.

The design of these parts is not just simulated on computer programs, but also underlined with field tests. Each final design in the engineering department is tested under real working conditions for a min. of 1.000.000 cycle before the parts are approved for mass production.

We are dedicated to perfection if we talk about high quality sealing.

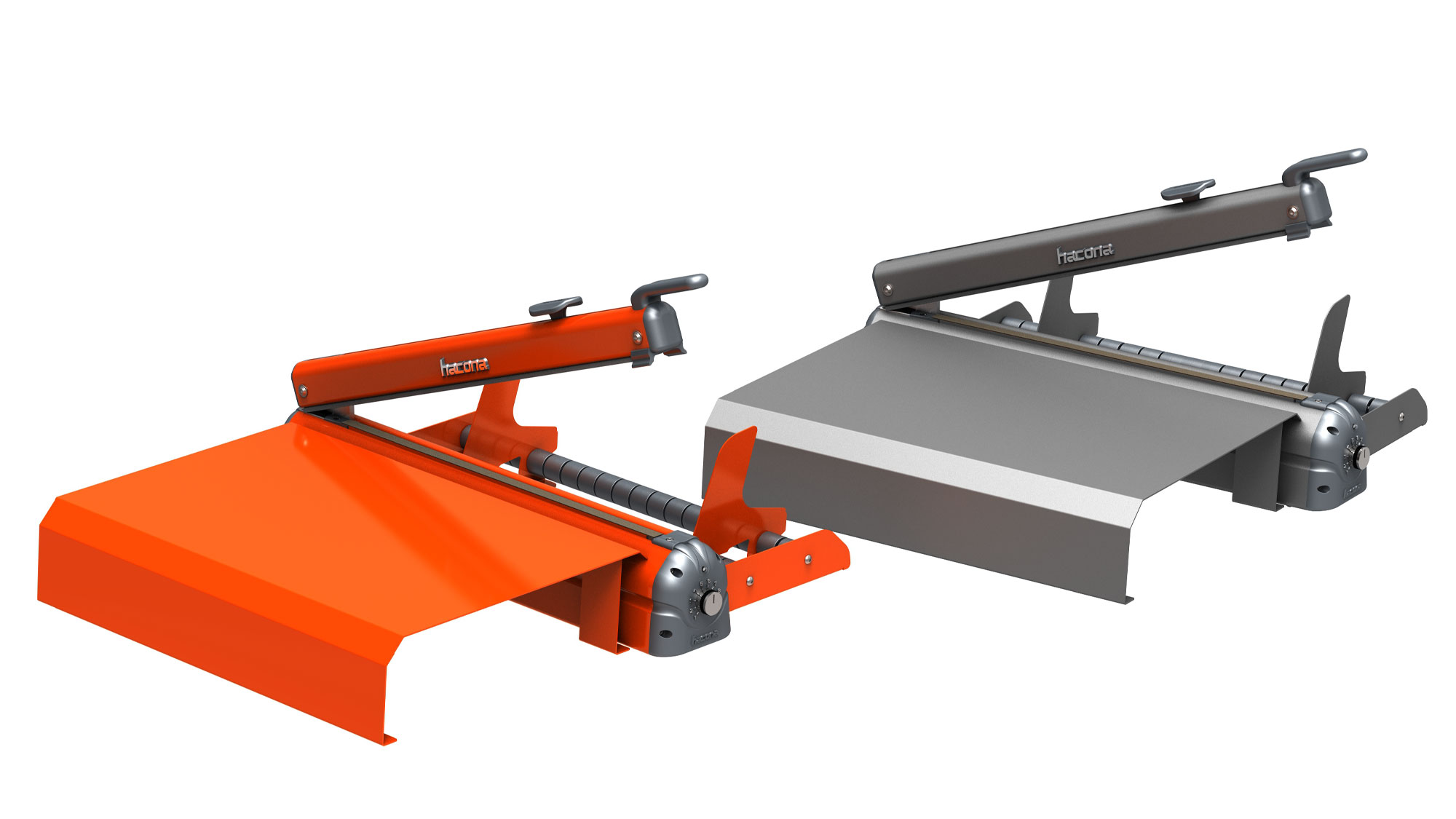

Offering endless possibilities with ergonomic design.

Each C-type heat sealer – poly bag sealer can be equipped with following accessories:

• Working table

• Film holding rolls with guiding plates

The C-type heat sealer – poly bag sealer can be used by itself as a table top heat sealer. By adding the working table or film holding rolls to the machine the ergonomic working is emphasized.

Each accessory can be added pcs. by pcs. to the machine. The combination possibilities depend on the user.

The working table supports the bag in front of the machine and assures totaly flat surface to lay the product on. If the product is extreme long, a second working table can be added and connected to the previous one.

The film holding rolls with the guiding plates can support different size of film rolls. Thanks to the split roll technology it is possible to unwind one roll without unwinding the other one. The guiding plates prevent the narrow film roll from falling to the side.

If several sizes of film rolls are used in the packaging process, a second set of film holding rolls with guiding plates can be added to the machine.