Machine body: Silver anodized surface

Machine body: Silver anodized surface

CI-type impluse sealing machines with silver anodized surface

All CI-type impulse sealing machines can be used in food- , pharmaceutical-and chemical industry. By anodizing (surface treatment) the machine frame the surface of the aluminium profile gets absolute smooth and strengthened. With this surface treatment the CI-type film sealing machine frame is now even more resistant agains scretches and mechanical impact.

The entire machine is designed to assure the highest safety. The machine body and the connecting parts are mounted so precisely, that there is not even a single gap between them. No free running cables and no openings on the machine frame. It all serves the safety!

The machine body and the sealing bar of each CI-type impulse heat sealer is made out of ultra strong magnesium aluminum profile. This technology assures super strong base and absolute flat surface for the special designed impulse sealing wire. In parallel we guarantee with the special designed aluminium ribs inside the frame also a proper and fast cooling of the sealing wires after the sealing cycle is finished.

ATTENTION: The surface is not acid-proof!

Machine color and surface treatment: silver anodized

IP protection class: IP 23 [IP]

Working safety:

* IP 23 protection class

* The machine corresponds to all effective EU regulations.

* The machine has got CE certificate

* Hacona produces all the products according to the ISO 9001 Quality - and ISO 14001 Environmental Control System.

C-type video: link

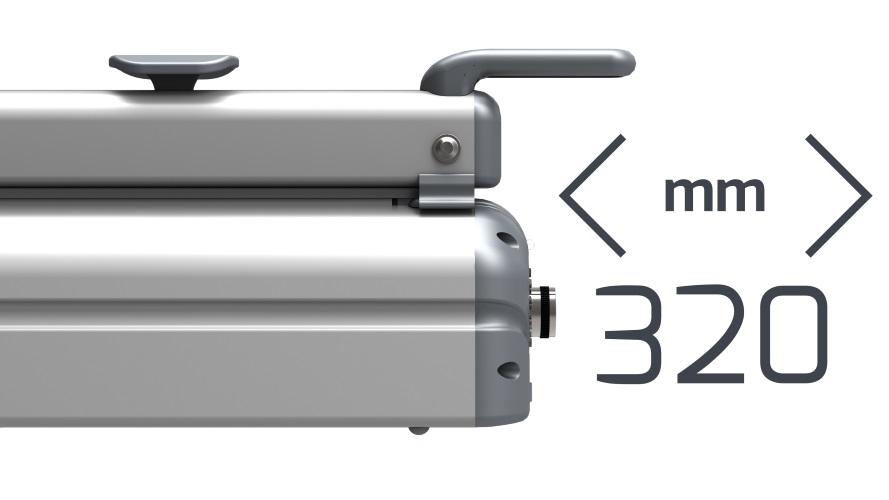

Technical data for 320 mm (12 inch) sealing bar length:

Parameters

Technical data for 320 mm (12 inch) sealing bar length:

Parameters

Sealing length: max. 320 [mm] (12 inch)

Sealing width: 2,5 [mm] (0,1 inch)

Max. sealable film width: max. 300 [mm] (11,81 inch)

Max. cutting length: max. 300 [mm] (11,81 inch)

Cutting with safety knife: The safety knife cuts the tubular film 8 mm (0,31 inch) above the sealing.

Max. sealable film thicknesses [Absolute thickness]:

max. 400 micron / PE-Polyetilene

max. 150 micron / PP-Polypropilene

max. 100 micron / PVC- Polyvinyl Clorid

max. 150 micron / (BOPP-Biaxal Oriented Polypropilene)

max. 150 micron / PA coated films, that have inside sealable film. Other laminated films, that have inside sealable film.

Max. sealing temperature: 136 [°C]

Max. sealing time: 6 [sec.]

Sealing time: The sealing time can be adjusted infinitely variable by the potentiometer scrolling button on a 0-10 scale. (The sealing time is depending largely on the type and the thickness of the sealable material!)

Machine capacity: max. 100 [sealings / hour]

Electrical connection:

230 V, 50 / 60 Hz [V, Hz] – for EU and UK power cord

110 V, 50 Hz [V, Hz] – for USA power cord

Machine consumption: 227 - max. capacity [W]

Machine consumption (in standby mode): 2 [W/h]

Consumption information:

The C-type and CI-type table top impulse sealer is working according to impulse operating principle. The machine is always in stand by mode and consumes only 2 W/h (power consumption). The sealing wire only heats up during the sealing process. During the sealing process the consumption of the machine is max. 227 W.

Electric cable length: 185 [cm] (73 inch)

Power: 0,99 [A]

Machine size (with open sealing bar): 530 x 95 x 300 (LxWxH) [mm] (21 x 3,7 x 12 inch)

Machine size (with closed sealing bar): 530 x 95 x 175 (LxWxH) [mm] (21 x 3,7 x 7 inch)

EU plug

EU plug

The plug on the power supply cord is produced as injection molded (it is not mounted on separately) plug! It can not be mounted later on or taken off!

The power cord is mechanically and electrically connected (on the machine side) inside the machine. It can not be disconnected from the machine.

Power cord length for C-type and CI-type machines are the same. Length are like follows:

Machine type - Cord length

C - 220 & CI - 220 -- app. 200 cm (80 inch)

C - 320 & CI - 320 -- app. 185 cm (74 inch)

C - 420 & CI - 420 -- app. 175 cm (70 inch)

C - 620 & CI - 620 -- app. 155 cm (62 inch)

C - 820 & CI - 820 -- app. 135 cm (54 inch)

ATTENTION: ALWAYS USE EARTH CONNECTION!