Machine body: Stainless stell – INOX finish

Machine body: Stainless stell – INOX finish

II-type / VI-type impulse sealing machines with stainless steel machine body. Suitable for food,-pharmaceutical and chemical industry applications.

Perfect look that reflects the quality - is one of the key aspects that our engineers have in mind when they develop a product. We do not accept even the slightest compromise in high quality and top appearance.

The entire machine is designed to assure the highest safety. The machine body and the connecting parts are mounted so precisely, that there is not even a single gap between them. No free running cables and no openings on the machine frame. It all serves the safety!

The sealing bar of each II-type / VI-type stainless steel impulse heat sealer is made out of ultra strong magnesium aluminum profile. This technology assures super strong base and absolute flat surface for the special designed industrial impulse sealing wire. In parallel we guarantee with the special designed aluminium ribs inside the sealing bar also a proper and fast cooling of the sealing wires after the sealing cycle is finished.

Machine color and surface treatment:

Machine body – stainless steel – INOX

Sealing bar – anodized aluminium

IP protection class: IP 31 [IP]

Working safety:

* IP 31 protection class

* The machine corresponds to all effective EU regulations

* The machine has got CE certificate

* Hacona produces all the products according to the ISO 9001 Quality - and ISO 14001 Environmental Control System

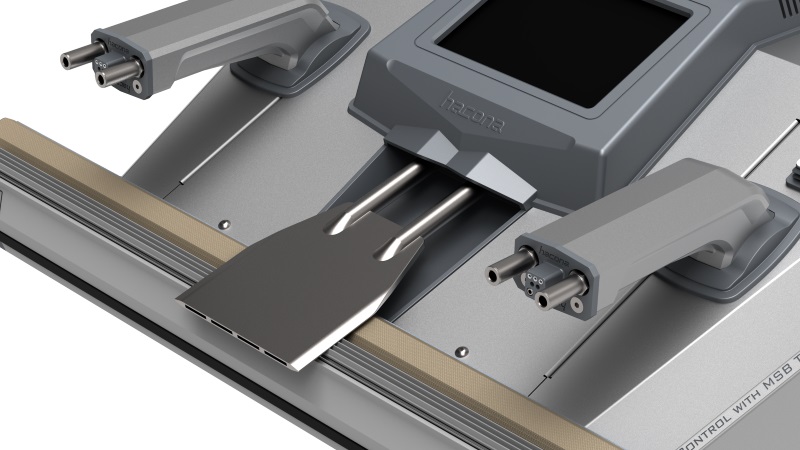

V – Type Big vacuum nozzle for high capacity vacuum & gas injection machine with rear vacuum outlet

V – Type Big vacuum nozzle for high capacity vacuum & gas injection machine with rear vacuum outlet

A flexible solution for high speed vacuum packaging and (optional) gas injection to be used for any type of industrial product.

(The vacuum machine has an integrated gas flush modul to be used for MAP – Modified Atmosphere Packaging!)

The machine is designed to vacuum air out of big size bags. With the different type and size of external vacuum pumps it is possible to vacuum up to 100 m3 / h air (max. 950 mbar vacuum level) out of the bag (ATTENTION: Depending from the connected vacuum pump type and size!). To operate the machine it is a must to connect an external vacuum pump or connect the machine to an existing vacuum sytem. The vacuum time or vacuum pressure can be adjusted on the controll board (HMI).

Further the machine has also an integrated standard gas flush modul. It is also possible to flush the bag with any kind of connected gas. The injected gas level or gas pressure can be adjusted digitaly through the machine setting (HMI).

Standard gas flush technical data:

● Tube outer diameter: 6 mm

● Max gas pressure: 6 bar

This industrial vacuum sealing machine is designed to seal thick packaging films with a maximum material thickness of 1000 micron, or bags which are very contaminated on the inside after filling. Further it is possible to seal very creasy films where the material thickness is in the sealing are very different in material thickness. Thanks to the high sealing pressure the sealing will be even and air tight.

● The sealing bars are pneumaticaly operated

● Machine can seal any type of thermoplastic film or laminated film with a sealable inside

layer where the sealing temperature is between 80 – 230 °C (app. 170 – 440 °F) - with Extra 1 option MAX 260°C (500°F) - temperature.

● Power consumption of the machine: app. 1800 W

(the power consumption depends from the sealing bar size, choosen to the machine!)

● Power consumption in stand by mode: app. 20 W / h

● Intelligent sealing current control (SMPS) with Digital temperature measurement (DTM)

● Machine settings: 5,4" touchdisplay HMI (Human Machine Interface)

● Working cycles can be adjusted and saved in 30 different programs

● Password protected multi level safety system

● Gas flushing function is included in the machine!

In the machine box the following will be included:

● user manual in all cases

● foot pedal if the two-hand start is not ordered

● power cord if stand is not ordered

The vacuum tube is connected to the vacuum nozzle through the rear outlet of the machine, thereby simplifying the threading of the bag.

It is recommended in special cases when a vacuum level above 90% is required.